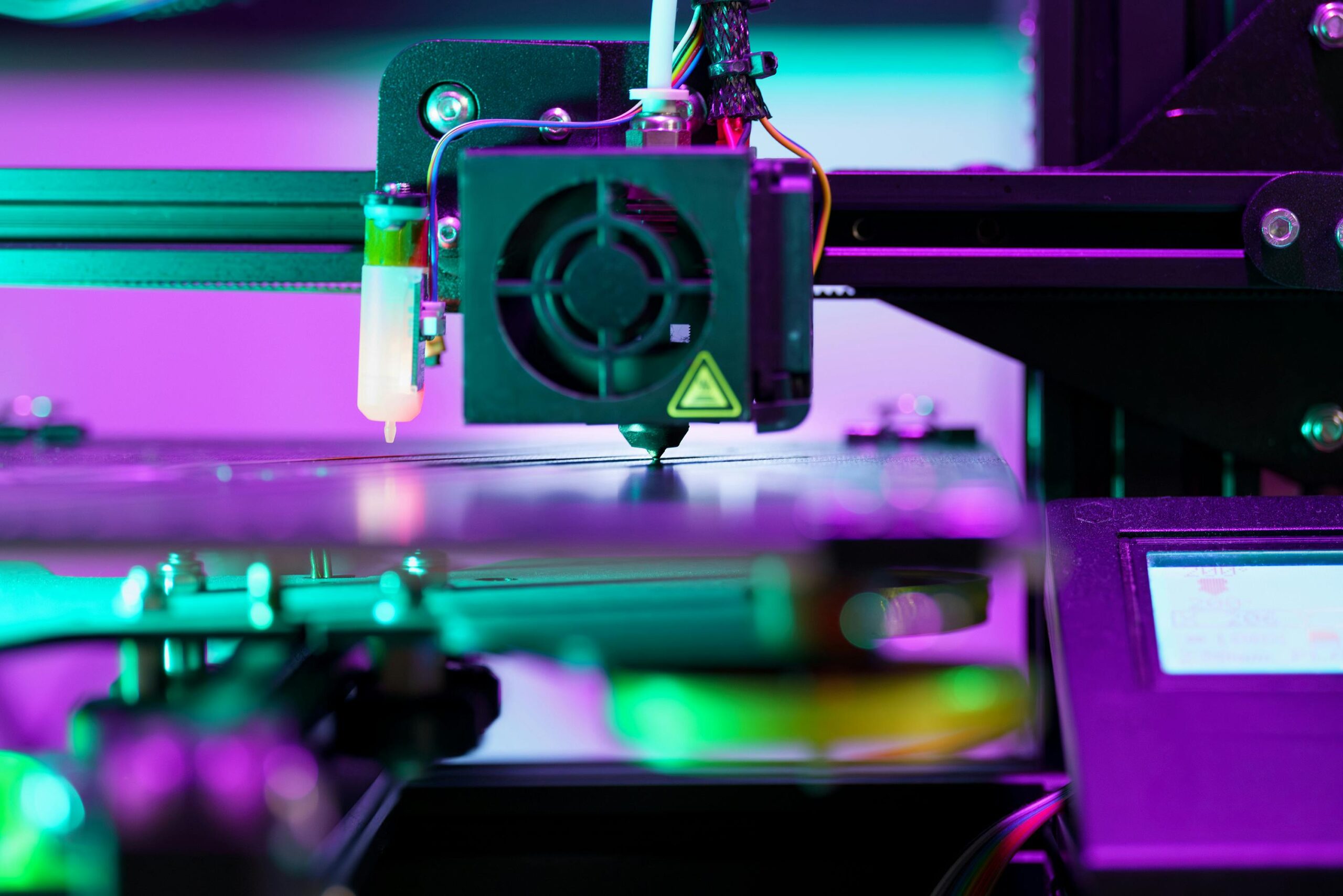

The manufacturing landscape is undergoing a profound transformation, driven by digital technologies that promise to reshape how products are designed, produced, and delivered to market.

Factory digitalization is no longer a futuristic concept but a present-day imperative for manufacturers seeking to remain competitive in an increasingly complex global marketplace. As industrial operations evolve from traditional mechanical systems to interconnected digital ecosystems, organizations are discovering unprecedented opportunities to optimize processes, reduce costs, and accelerate innovation. The convergence of advanced technologies such as artificial intelligence, Internet of Things (IoT), cloud computing, and data analytics is creating a new paradigm where physical and digital worlds merge seamlessly on the factory floor.

🏭 The Digital Manufacturing Revolution: A Paradigm Shift

Digital transformation in manufacturing represents far more than simply implementing new software or upgrading equipment. It fundamentally reimagines how factories operate, creating intelligent production environments where data flows continuously between machines, systems, and human operators. This revolution is characterized by real-time visibility, predictive capabilities, and adaptive manufacturing processes that respond dynamically to changing conditions.

Modern digitalization frameworks integrate multiple technological layers, creating a cohesive architecture that connects everything from individual sensors on production equipment to enterprise resource planning systems. This interconnectedness enables manufacturers to capture valuable insights from every stage of production, transforming raw data into actionable intelligence that drives continuous improvement.

The impact extends beyond operational efficiency. Digital frameworks are fundamentally changing business models, enabling manufacturers to offer new services, customize products at scale, and respond to market demands with unprecedented agility. Companies that embrace comprehensive digitalization strategies are reporting significant improvements across multiple performance indicators, from reduced downtime to enhanced product quality and accelerated time-to-market.

Core Components of Advanced Factory Digitalization

A robust factory digitalization framework comprises several interconnected technological components, each playing a critical role in creating a fully integrated manufacturing ecosystem. Understanding these elements is essential for developing an effective implementation strategy.

Industrial Internet of Things (IIoT) Infrastructure

At the foundation of factory digitalization lies the Industrial Internet of Things, a network of connected sensors, devices, and machines that continuously collect and exchange data. IIoT infrastructure transforms traditional equipment into intelligent assets capable of self-monitoring, communicating status updates, and even predicting maintenance needs before failures occur.

These connected devices generate massive volumes of data about machine performance, environmental conditions, energy consumption, and product quality. When properly analyzed, this information provides manufacturers with unprecedented visibility into their operations, revealing inefficiencies and opportunities that would otherwise remain hidden.

Advanced Analytics and Artificial Intelligence

The true value of digitalization emerges when raw data is transformed into meaningful insights through advanced analytics and artificial intelligence. Machine learning algorithms can identify patterns in production data, predict quality issues, optimize production schedules, and recommend process improvements with a precision that exceeds human capabilities.

AI-powered systems continuously learn from historical and real-time data, becoming more accurate and valuable over time. These capabilities enable predictive maintenance strategies that minimize unplanned downtime, quality control systems that detect defects before products leave the factory, and demand forecasting models that optimize inventory levels.

Cloud Computing and Edge Processing

Modern digitalization frameworks leverage both cloud computing and edge processing to balance the need for centralized data management with the requirement for real-time responsiveness. Cloud platforms provide scalable infrastructure for data storage, complex analytics, and cross-facility integration, while edge computing enables immediate processing of time-sensitive data directly on the factory floor.

This hybrid approach ensures that critical decisions can be made instantaneously without network latency, while still maintaining comprehensive data repositories for long-term analysis and strategic planning. Cloud-based systems also facilitate collaboration across geographically distributed manufacturing sites, enabling organizations to share best practices and standardize processes globally.

⚙️ Transforming Operations Through Digital Excellence

The implementation of advanced digitalization frameworks delivers tangible benefits across every aspect of manufacturing operations. These improvements compound over time, creating sustainable competitive advantages for forward-thinking organizations.

Enhanced Production Efficiency and Throughput

Digital systems optimize production flows by identifying bottlenecks, balancing workloads, and minimizing changeover times. Real-time monitoring enables rapid response to deviations from planned performance, while predictive algorithms anticipate issues before they impact production schedules.

Manufacturers implementing comprehensive digitalization frameworks report productivity increases ranging from 15% to 30%, achieved through better equipment utilization, reduced cycle times, and elimination of non-value-adding activities. These gains translate directly to improved profitability and capacity expansion without corresponding capital investments in additional equipment.

Quality Assurance and Zero-Defect Manufacturing

Digital quality management systems leverage computer vision, sensor data, and AI algorithms to detect defects with greater accuracy and consistency than traditional inspection methods. These systems can identify subtle variations that human inspectors might miss, while documenting comprehensive quality data for regulatory compliance and continuous improvement initiatives.

By implementing in-process quality monitoring rather than relying solely on end-of-line inspection, manufacturers can identify and correct problems immediately, preventing the production of defective units and reducing waste. This approach moves organizations closer to the ideal of zero-defect manufacturing, where quality is built into every process step rather than inspected afterward.

Predictive Maintenance and Asset Optimization

Perhaps one of the most impactful applications of factory digitalization is predictive maintenance, which uses sensor data and machine learning to anticipate equipment failures before they occur. This approach transforms maintenance from a reactive or scheduled activity into a proactive strategy that maximizes equipment availability while minimizing maintenance costs.

Predictive maintenance systems analyze vibration patterns, temperature fluctuations, energy consumption, and other indicators to identify early warning signs of impending failures. This enables maintenance teams to schedule interventions during planned downtime, order parts in advance, and prevent catastrophic failures that could halt production for extended periods.

🚀 Innovation Acceleration Through Digital Capabilities

Beyond operational improvements, digitalization frameworks serve as powerful enablers of innovation, allowing manufacturers to experiment with new approaches, launch products faster, and adapt to changing market conditions with unprecedented speed.

Digital Twins and Virtual Commissioning

Digital twin technology creates virtual replicas of physical assets, processes, or entire factories, enabling manufacturers to test changes, optimize parameters, and troubleshoot problems in a risk-free digital environment before implementing modifications in the real world. This capability dramatically reduces the time and cost associated with process improvements and new product introductions.

Virtual commissioning extends this concept to new production lines, allowing engineers to design, program, and validate complete manufacturing systems digitally before any physical equipment is installed. This approach can reduce commissioning time by 50% or more while eliminating costly errors that would otherwise be discovered during physical startup.

Flexible Manufacturing and Mass Customization

Digital frameworks enable flexible manufacturing systems that can quickly adapt to produce different product variants without extensive retooling or reconfiguration. This capability is increasingly important as consumer preferences shift toward customized products and market demands become more volatile.

Software-defined manufacturing processes can be reconfigured through digital commands rather than physical changes, allowing production lines to switch between products in minutes rather than hours. This flexibility enables manufacturers to offer customization options that would be economically impossible with traditional production systems, opening new market opportunities and revenue streams.

Implementation Strategies for Successful Digitalization

While the benefits of factory digitalization are compelling, successful implementation requires careful planning, strategic investment, and organizational change management. Organizations that approach digitalization as a comprehensive transformation rather than a series of isolated technology projects achieve substantially better results.

Assessment and Roadmap Development

Effective digitalization begins with a thorough assessment of current capabilities, identification of priority improvement areas, and development of a phased implementation roadmap. This strategic approach ensures that investments deliver measurable value while building foundational capabilities that support future initiatives.

Organizations should evaluate their digital maturity across multiple dimensions, including technology infrastructure, data management capabilities, workforce skills, and organizational culture. This assessment provides a baseline for measuring progress and helps prioritize initiatives based on potential impact and implementation feasibility.

Building a Robust Data Architecture

Data is the foundation of factory digitalization, and establishing a robust data architecture is critical for long-term success. This architecture must address data collection, storage, integration, security, and governance across diverse systems and sources.

Successful manufacturers implement standardized data models that ensure consistency across different equipment types and production areas. They establish clear data ownership and quality standards, implement cybersecurity measures appropriate for industrial environments, and create analytics platforms that make data accessible to stakeholders throughout the organization.

Workforce Development and Change Management

Technology alone does not ensure successful digitalization. Organizations must invest in workforce development programs that build digital literacy, analytical capabilities, and problem-solving skills throughout the organization. This includes training for operators who interact with digital systems daily, engineers who design and optimize processes, and managers who make strategic decisions based on data insights.

Change management is equally important, as digitalization often requires new ways of working, different decision-making processes, and shifts in organizational structure. Successful implementations engage employees early, communicate the vision and benefits clearly, and celebrate successes to build momentum and organizational commitment.

💡 Overcoming Common Implementation Challenges

Despite the clear benefits, many organizations struggle with factory digitalization initiatives. Understanding common challenges and proven mitigation strategies helps organizations avoid pitfalls and accelerate their digital transformation journey.

Legacy System Integration

Most manufacturing facilities operate a mix of equipment spanning multiple generations, from cutting-edge connected machines to decades-old mechanical systems. Integrating these diverse assets into a cohesive digital framework presents significant technical challenges.

Modern digitalization platforms address this challenge through flexible connectivity options, including retrofit sensors for older equipment, protocol converters that translate between different communication standards, and middleware layers that normalize data from diverse sources. While integration requires upfront investment, the ability to leverage existing assets extends their useful life and improves return on investment.

Cybersecurity Considerations

As factories become more connected, they face increased cybersecurity risks that could compromise operations, intellectual property, or product quality. Manufacturing cybersecurity requires specialized approaches that balance security with operational requirements, as traditional IT security measures may not be appropriate for industrial control systems.

Comprehensive security strategies include network segmentation that isolates critical systems, continuous monitoring for anomalous behavior, rigorous access controls, and incident response plans tailored to manufacturing environments. Organizations must also address supply chain security, ensuring that third-party equipment and software meet appropriate security standards.

Demonstrating Return on Investment

Quantifying the return on investment for digitalization initiatives can be challenging, as benefits often span multiple areas and accrue over time. Organizations should establish clear metrics before implementation, including both operational measures like equipment effectiveness and business outcomes like revenue growth or customer satisfaction.

Successful organizations start with pilot projects that deliver quick wins and provide proof points for broader investment. They document benefits comprehensively, including hard savings like reduced downtime and soft benefits like improved decision-making or enhanced innovation capabilities.

🌐 The Future of Manufacturing Digitalization

Factory digitalization continues to evolve rapidly, with emerging technologies promising even greater capabilities in the coming years. Understanding these trends helps manufacturers prepare for the next phase of digital transformation.

Autonomous manufacturing systems that require minimal human intervention are moving from research laboratories to production environments. These systems combine AI, robotics, and advanced sensors to create self-optimizing factories that continuously improve their own performance.

Augmented reality technologies are transforming how workers interact with digital information on the factory floor, overlaying real-time data, instructions, and diagnostic information onto physical equipment. These interfaces make complex information accessible and actionable, enhancing both productivity and quality.

Blockchain technology is beginning to address supply chain transparency and traceability challenges, creating immutable records of component provenance, production conditions, and quality verification. This capability is particularly valuable in regulated industries where comprehensive documentation is essential.

Building Sustainable Competitive Advantage Through Digitalization

The most successful manufacturers view digitalization not as a destination but as an ongoing journey of continuous improvement and innovation. They build organizational capabilities that enable rapid adoption of new technologies, create cultures that embrace data-driven decision-making, and establish partnerships that provide access to emerging capabilities.

This approach creates sustainable competitive advantages that compound over time. As digital systems accumulate more data and organizational capabilities mature, the gap between digital leaders and laggards widens, making it increasingly difficult for late adopters to catch up.

Manufacturers that commit to comprehensive digitalization strategies position themselves to thrive in an increasingly complex and competitive global marketplace. They gain the agility to respond to disruptions, the efficiency to maintain profitability despite margin pressures, and the innovation capabilities to create new value for customers.

The revolution in manufacturing digitalization represents a fundamental shift in how products are made and how manufacturing organizations compete. Advanced digitalization frameworks unlock efficiency improvements that directly impact profitability while enabling innovation that drives growth and market differentiation. As technologies continue to mature and implementation best practices become established, the question is no longer whether to digitalize but how quickly and comprehensively to pursue this transformative opportunity. Organizations that act decisively, invest strategically, and commit to the organizational changes required will emerge as the manufacturing leaders of tomorrow, setting new standards for operational excellence and innovation in an increasingly digital world. 🏆

Toni Santos is a technology researcher and industrial innovation writer exploring the convergence of human intelligence and machine automation. Through his work, Toni examines how IoT, robotics, and digital twins transform industries and redefine efficiency. Fascinated by the collaboration between people and intelligent systems, he studies how predictive analytics and data-driven design lead to smarter, more sustainable production. Blending engineering insight, technological ethics, and industrial foresight, Toni writes about how innovation shapes the factories of the future. His work is a tribute to: The evolution of human-machine collaboration The intelligence of connected industrial systems The pursuit of sustainability through smart engineering Whether you are passionate about automation, industrial technology, or future engineering, Toni invites you to explore the new frontiers of innovation — one system, one signal, one breakthrough at a time.